Feature

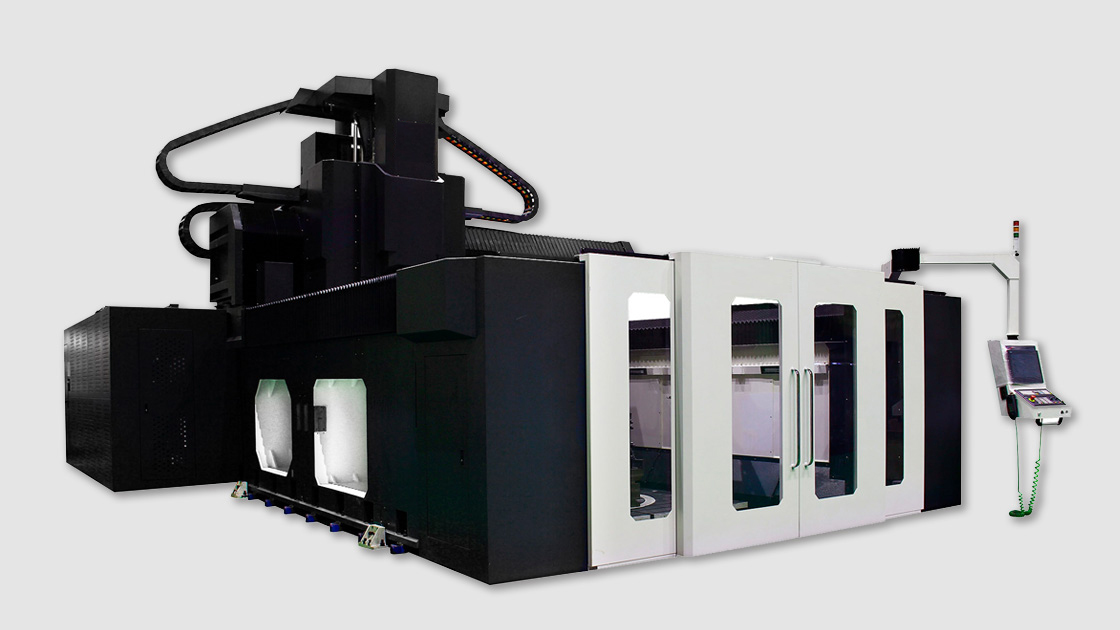

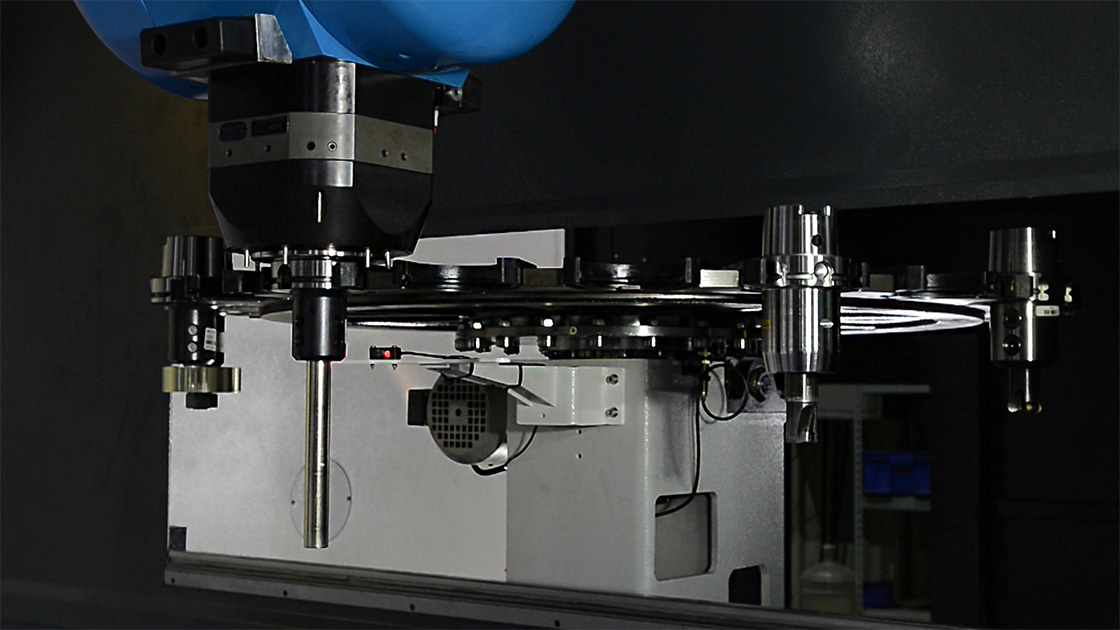

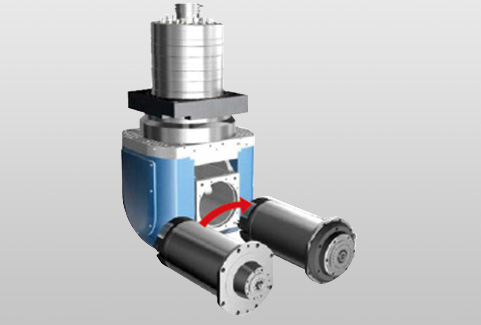

Changeable Spindle

Automatic spindle or head change system with contentious C axes

for different type of application up to spindle motor 72kw 1000Nm torque.

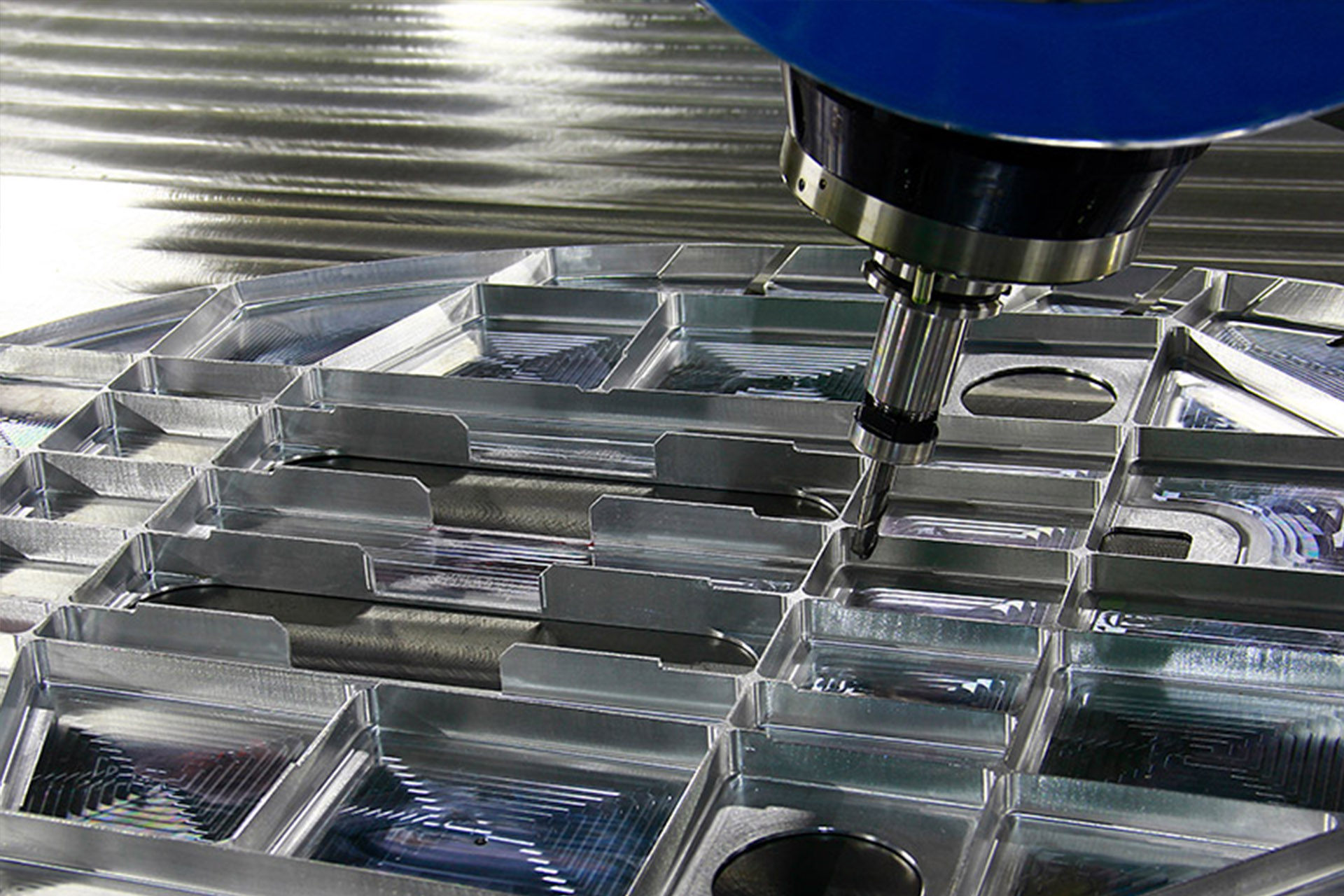

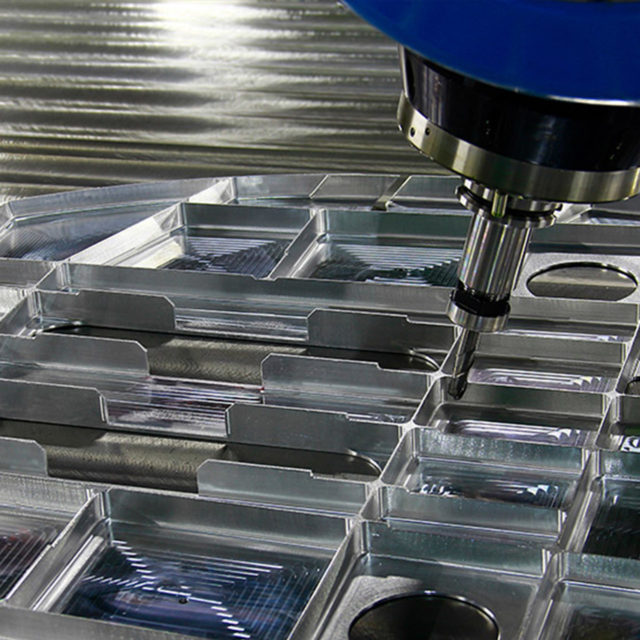

Enables intensive machining of steel and super alloys from rough milling to finishing operations.

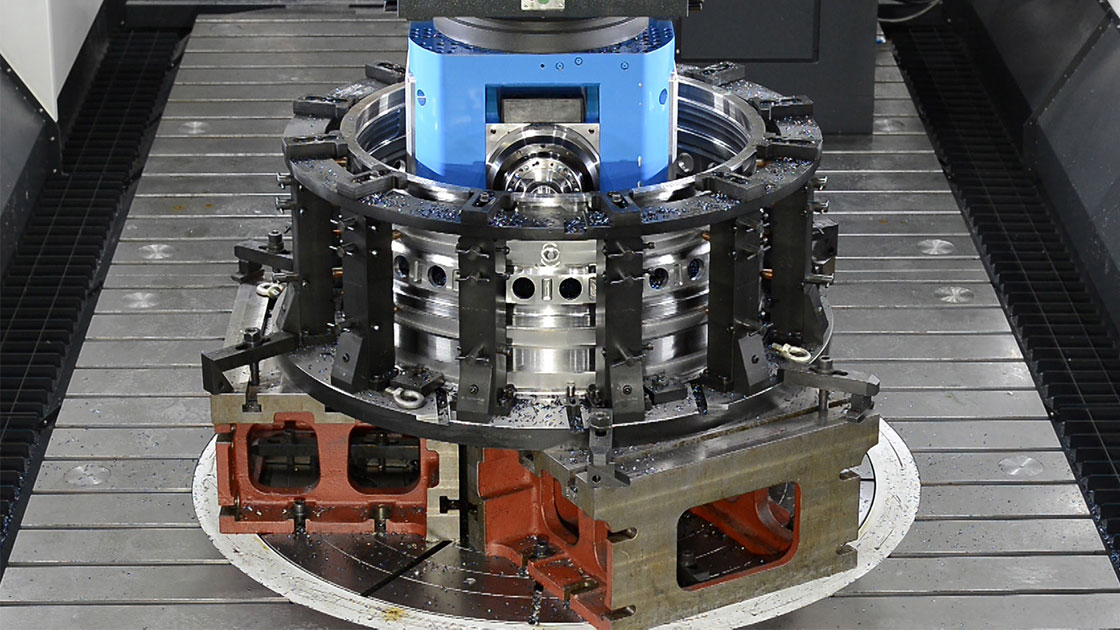

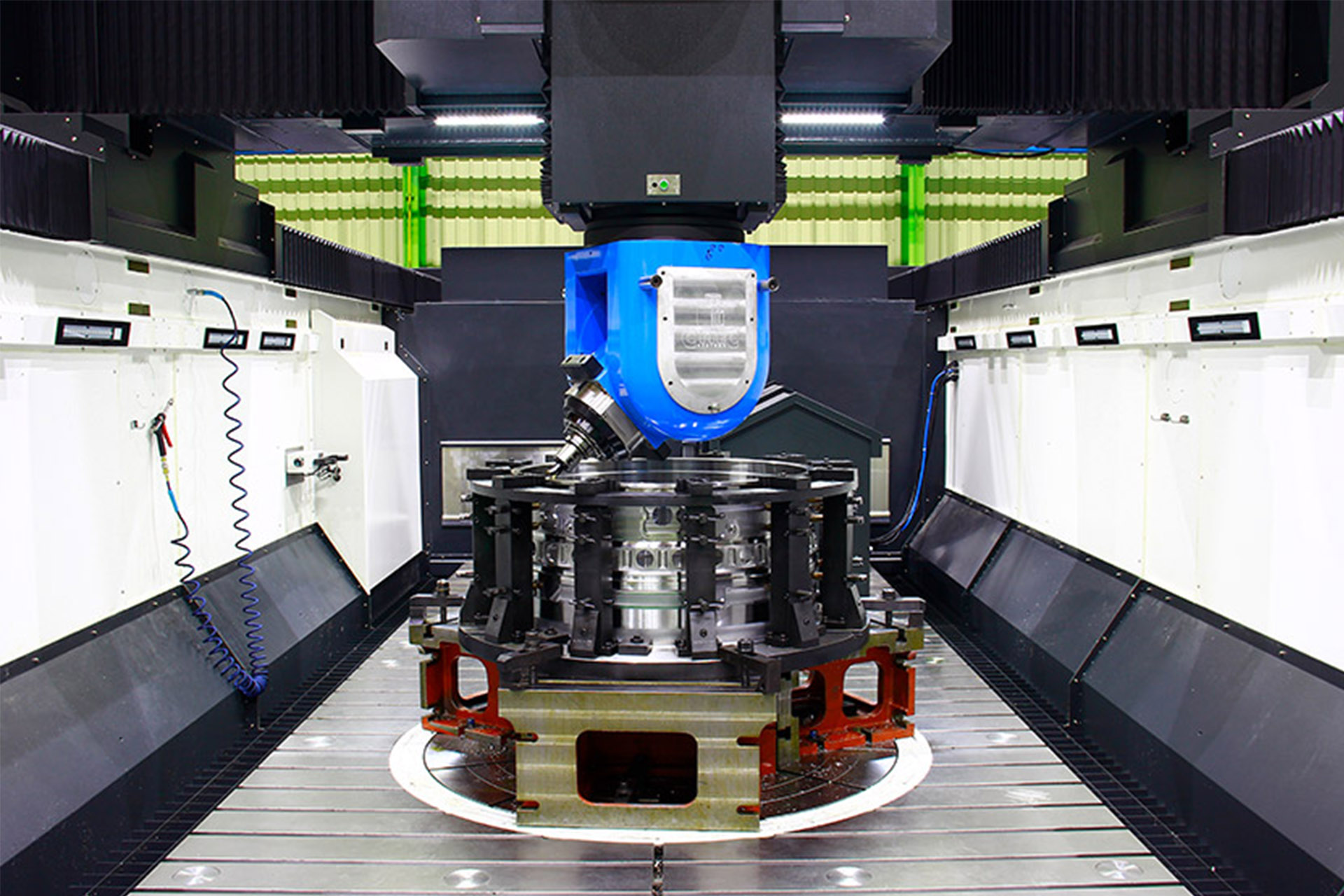

Embedded Working Table

-Continuous Rotary Tables with DD motor Hydraulic Brake Clamping and direct measuring system.

-Turning tables from 300 to 500 rpm up to 70kw and 8,000Nm torque.

Simultaneous 6-axis cutting

This simultaneous 6-axis machining center is capable of multi-axis processing with one chucking system. When combined with the advanced controller, the machine can perform high-precision machining on complex surfaces.

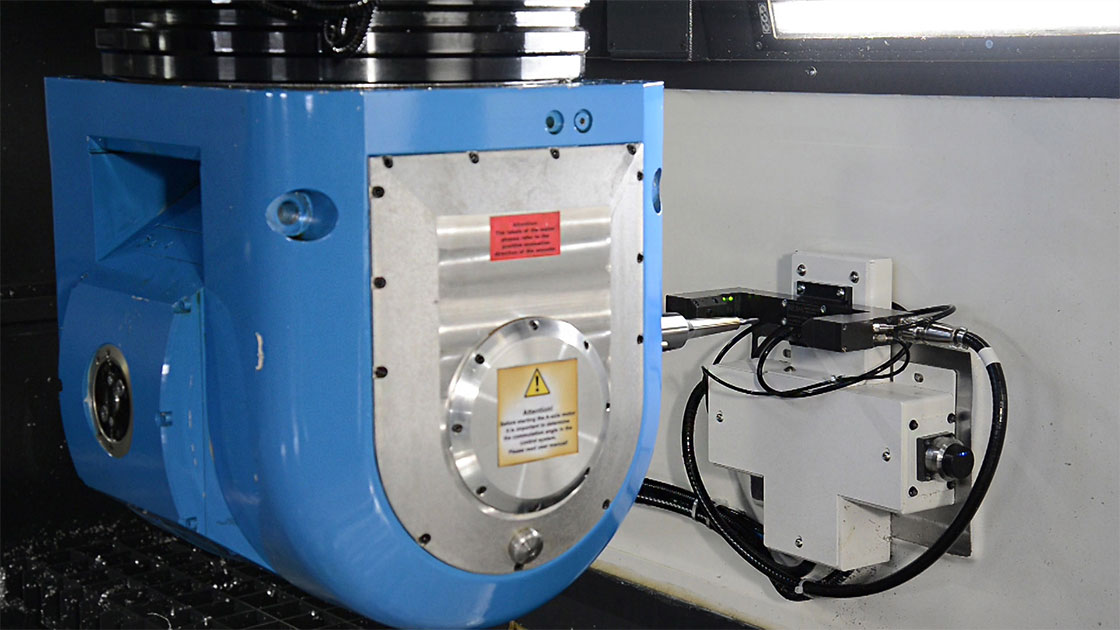

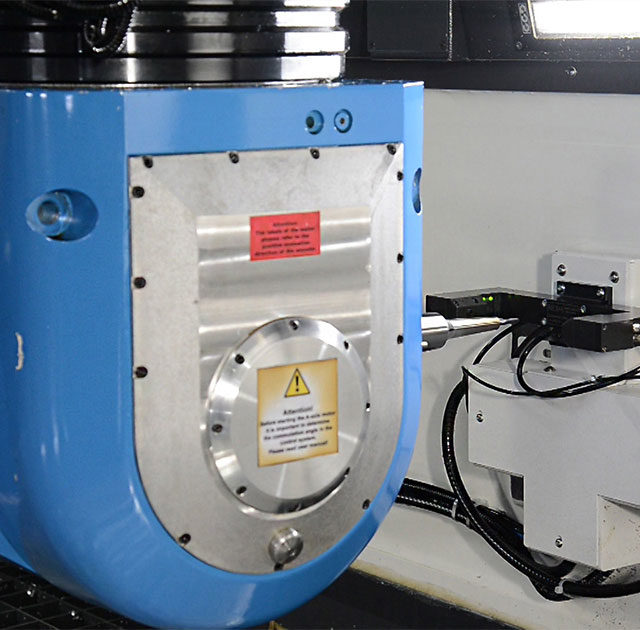

Torque motor

-High-efficiency permanent magnet, resulting in zero magnet degradation.

-High dynamic response, high torque, and high rotation speed.

-Equipped with high-resolution ring optical encoders, achieving perfect precision.

-Direct-drive motor caus

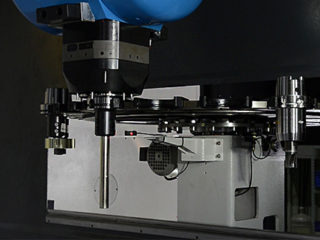

Automatic Tool Changer (ATC)

The umbrella-type tool magazine provide the smooth, quiet, and accurate position. The material of tool clamper is engineering composite plastic, which provides the stalbe clamping force and excellent coverage, and protects the spindle and tool magazine from improper tool changing. The tool changer is checked by tool holder load running-in test and achieves the requirements of stable, quick, easy, reliable and long service life.

Full Closed-loop Control

Temperature Control System

- Applicable Industry

- Aerospace

- Year

- 2016

- Technology

- Advanced

- Motor type

- Linear motor driving

- Materials

- Application on titanium nickel base alloy