Features

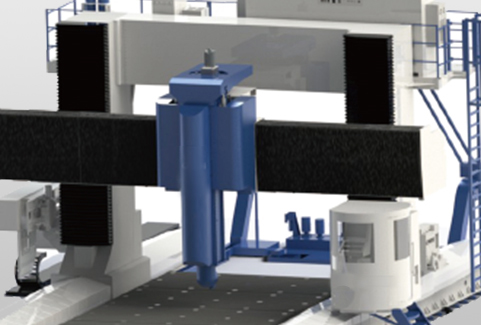

Z&W-axis Design-axis Design

-Z-axis is driven by servo motor and lead screw,it can steadily provide the power foe heavy duty machining,and achieve the best response of cutting.

-A high response closed-loop hydraulic counterweight device is utilized to support the headstock and balance the load of Z-axis motor for optimum precision and better acceleration.Moreover,the headstock will be fully supported and not fall due to gravity even when emergency power off.

-W-axis is optional,which can raise the height for more extensive machining area.

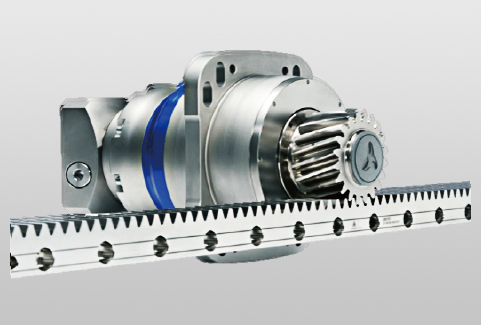

Driven by Rack and Pinion

X/Y-axis is driven by high-rigidity rack and pinion,and equipped with master-slave double servo motors to eliminate backlash.it can ensure the movement of X/Y axis not be affected by backlash,where by achieving the demand for high-precision.

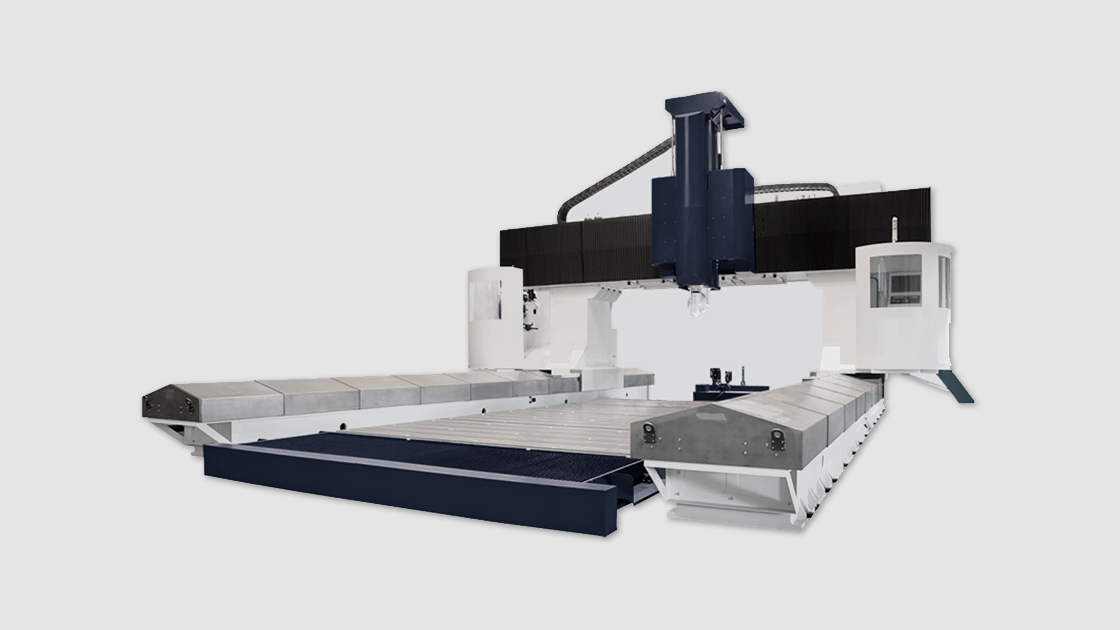

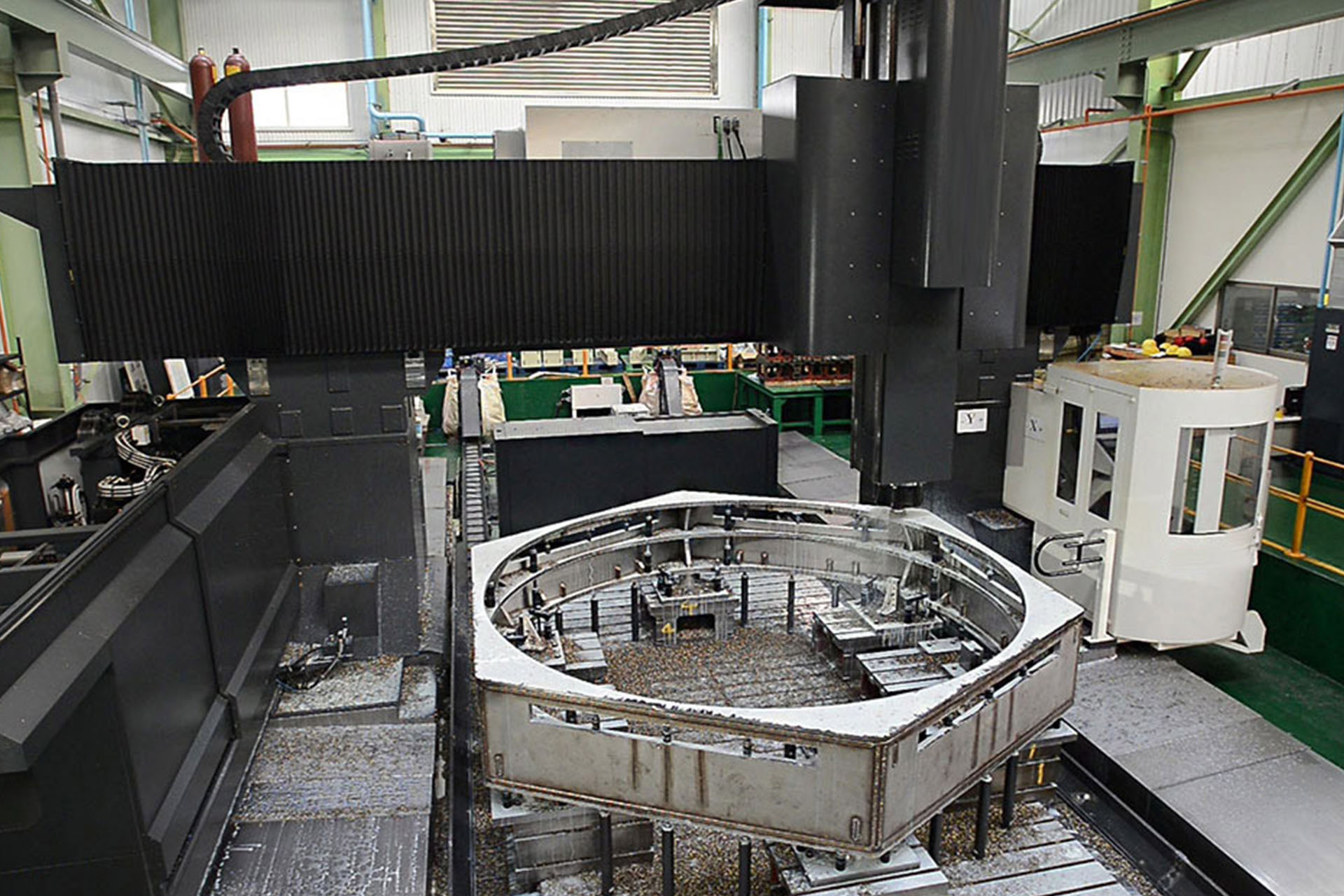

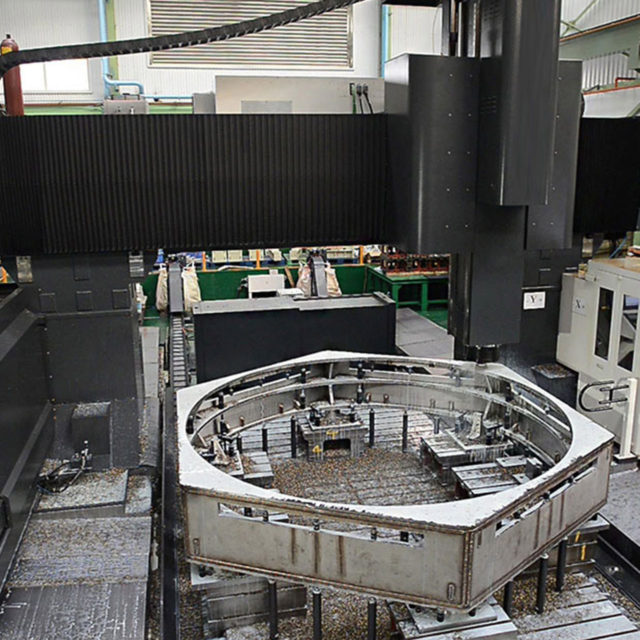

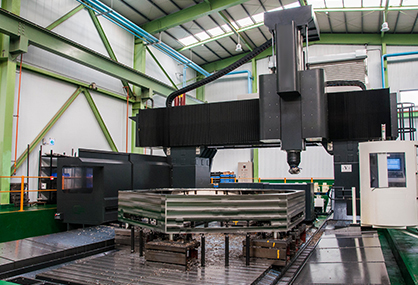

Large Cutting Space

Open space is available for machining and unloading large parts . The fixed table is designed for heavy-loaded workpiece , and therefore the machining is independent of the weight of the workpiece .

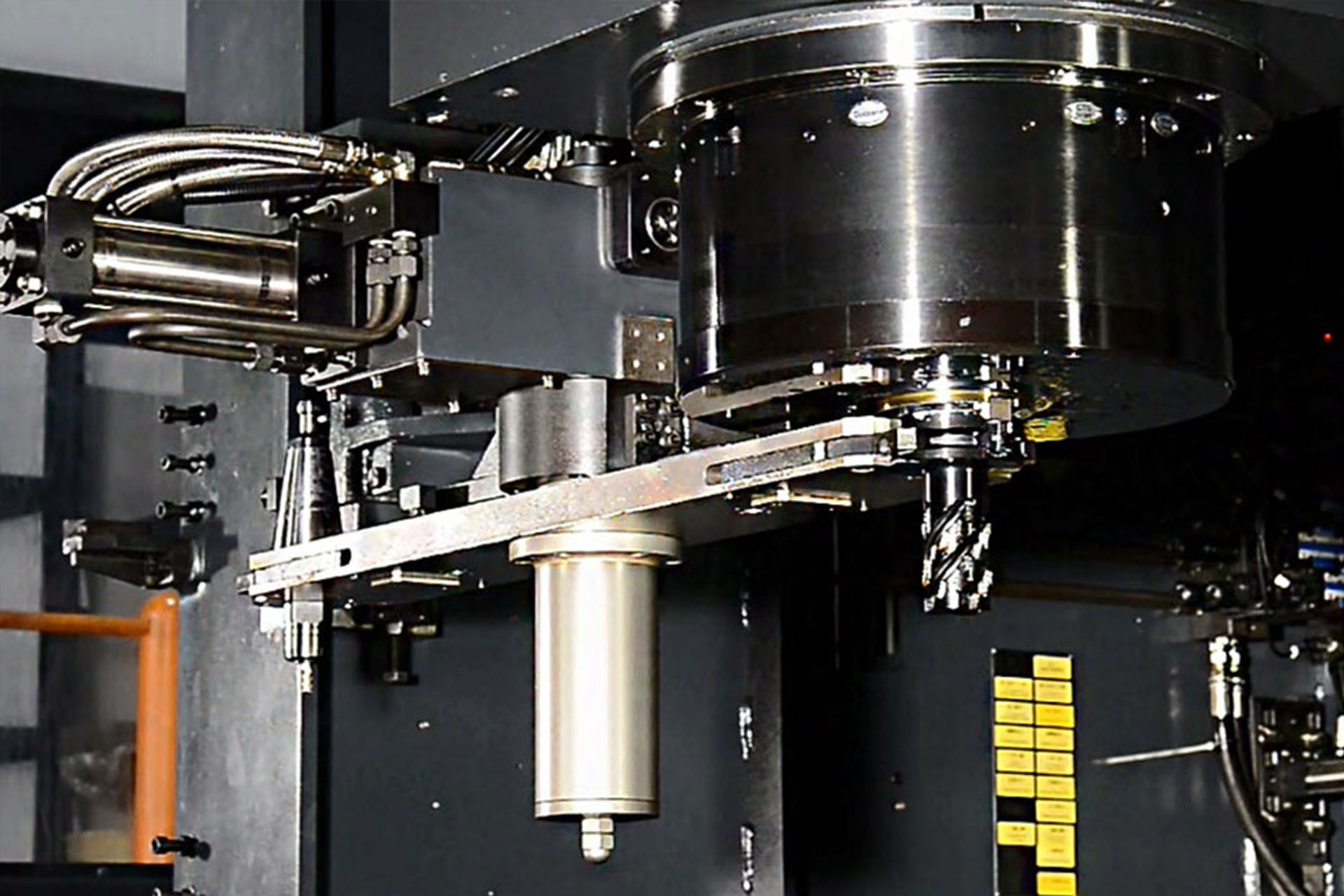

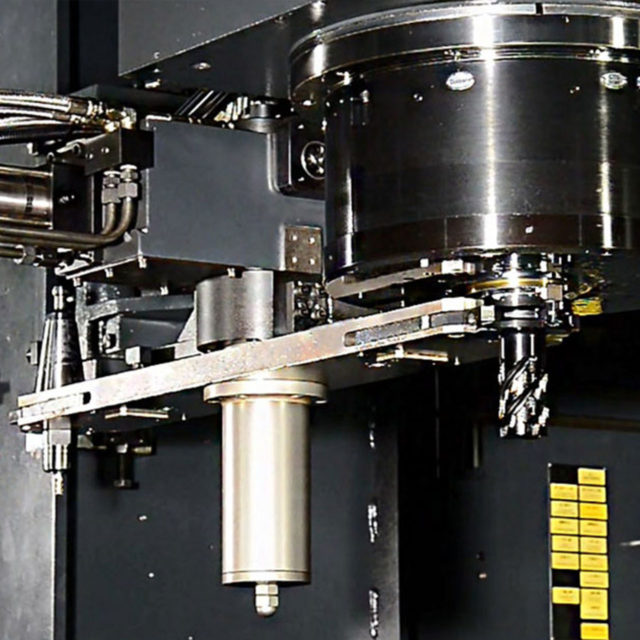

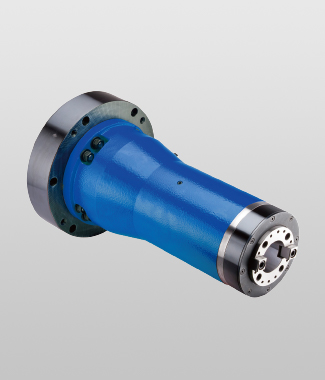

Angular Heads

Tool Holder: BT50

C-axis Angle: 5 degree

Max. Speed: 3,500 rpm

Max. Cutting Load: 650Nm

Tool Holder: BT50

C-axis Angle: 5 degree

Max. Speed: 3,500 rpm

Max. Cutting Load: 300Nm

Tool Holder: BT50

C-axis Angle: 5 degree

Max. Speed: 3,500 rpm

Max. Cutting Load: 650Nm

- Industries

- Energy, Machinery, Photonics

- Materials

- Variety of Difficult Materials

- Technology

- Advanced

- Processing Space

- Wide

- Year

- 2017