Ask for catalog Other inquiries View all products

Features

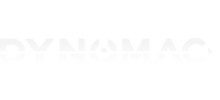

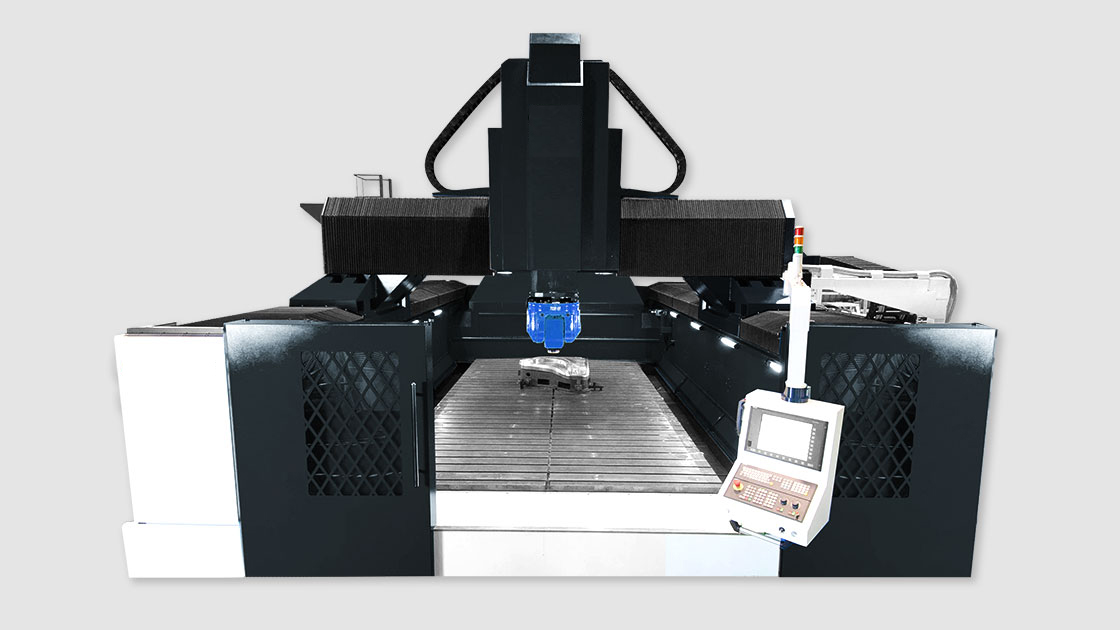

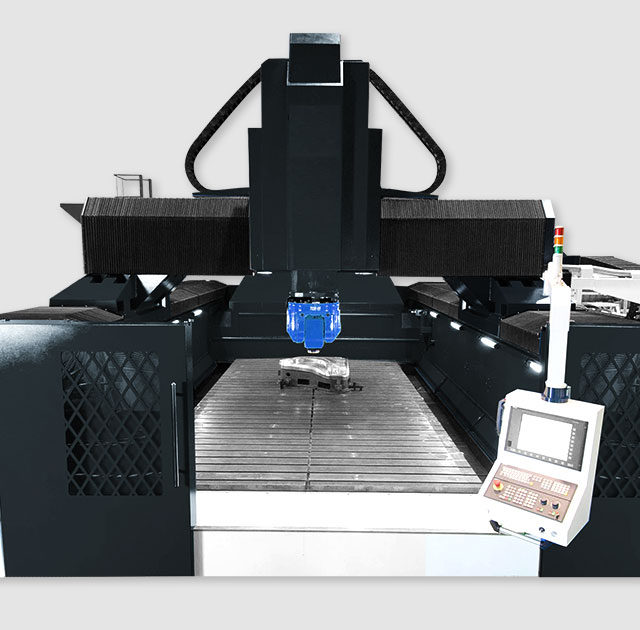

Designed to achieve maximum quality results for complex roughing operations when machining titanium, steel and other alloys. As well as for high-speed machining large structural elements for applications in the aerospace and energy industries.

Structure Design that can support both Heavy duty and high speed cutting

-One piece cast iron shoulders made high structural rigidity and a high degree of vibration damping to guarantee the best surface finishing and a longer tool life.

–Y axes cross beam bridge with high rigid oversize design.

–Z axes column using Box in Box design with duels drive and 4 linear guide ways.

MILLING HEADS WITH NEW GENERATION TORQUE DRIVES.

High speed torque motor with direct drive technology is adopt to B/C axis.

-Increased power and torque of the milling head for high efficient simultaneous machining is possible to reach a new level of high dynamic milling.

-High dynamic response, high torque, and high rotation speed thanks to the “Direct Drive” technology

– The sophisticated cooling technology of the coils offers 30% more power very high efficiency and dynamic

– Maintenance-free through the use of mechanical elements without frictions

SPINDLES

Can be equipped with motor spindles from a wide product range: from the powerful rough machining spindle up to high speed-spindles Power range 21 up to 60 kW

As an Option: Automatic head head-exchange or spindle motor.

Driven by linear motor

All axes driving system carry on with SIEMENS linear motor driving system

-Backlash free high position accuracy

-Free of wear due to friction free drive concept

-Fewer parts (reduce ball screw/ nuts, bearings, coupling

-Simple structure with long terms accuracy and easy maintenance

-Best Dynamic cutting responds

- Applicable Industry

- Aerospace, Automobile

- Year

- 2016

- Technology

- Advanced

- Motor type

- Linear motor driving

- Project

- Investment impacts