Why Dynomac

If you are a part manufacturer, it is vital to invest in a production machine that offers wide range of solutions with a relatively small investment.

All-in-One machine.

Built for the ones who do not want to limit their production capabilities, with probably the best machines prices in the market.

Heavy duty cutting.

High speed machining.

THE DESIGN

Rigid Structure

ADVANCED DESIGN

The Structure

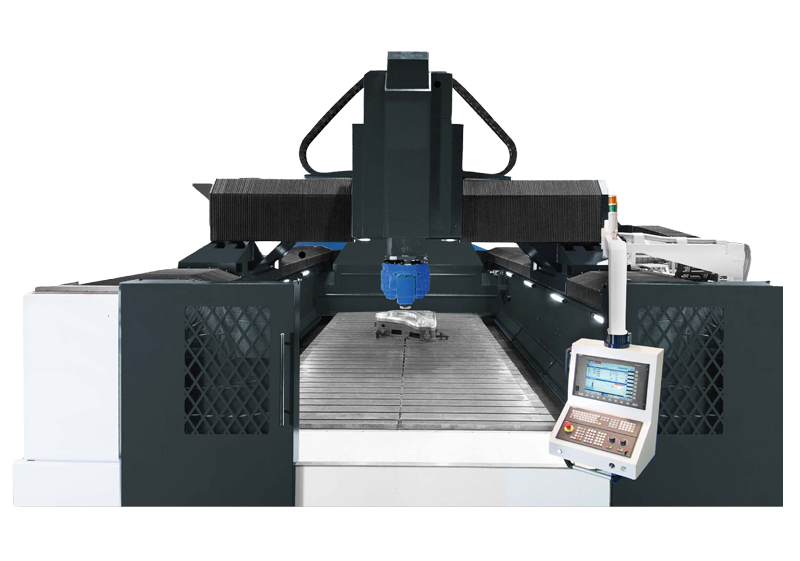

Massive cast iron one-piece column design with high vibration resistance supporting dynamic and heavy cutting performances.

Y axes

Y axes crossbeam bridge with oversized highly rigid box structure design.

Headstock

Z axes column headstock use double high rigid Box in Box structure with dual drive system and 4 linear guideways.

Structure optimization

The structure is optimized through using the most advanced FEM analysis and drive systems of the most recent generation.

HIGH SPEED, HIGH ACCURACY

Our machine’s linear motors are able to achieve the best output performances with the best dynamic cutting response.

LINEAR GUIDEWAYS

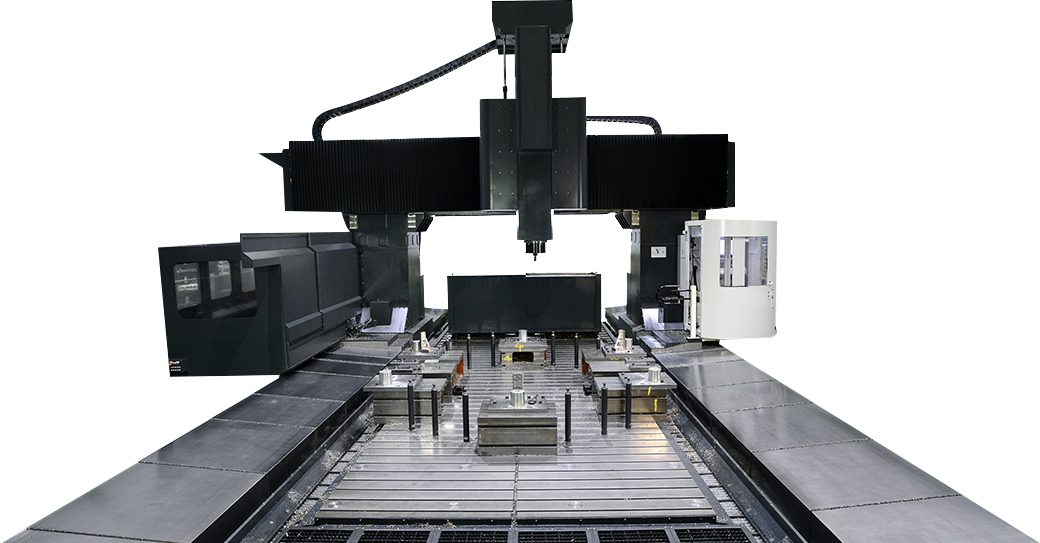

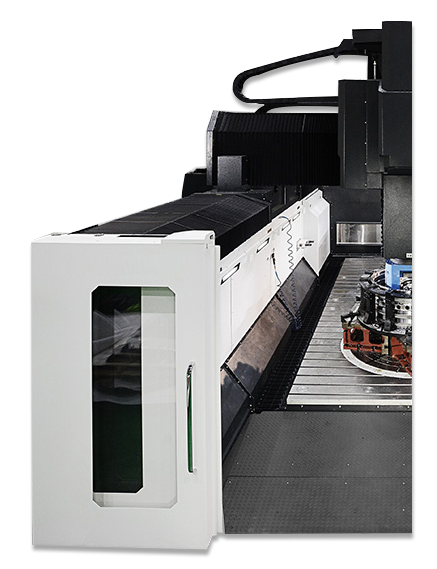

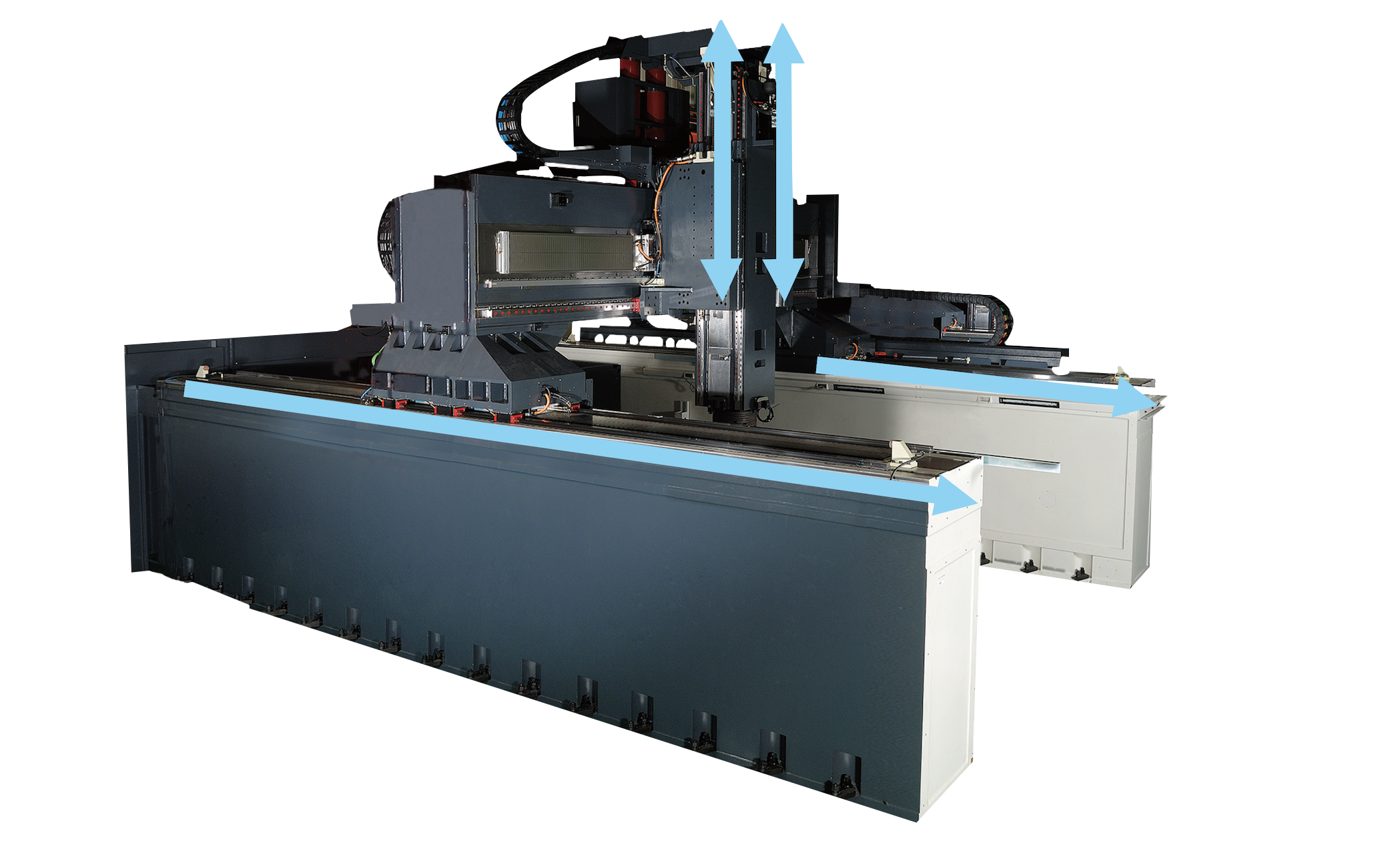

The gantry is supported by the symmetrical double walls using two roller linear guideways on each side.

WIDE CHOICE OF SPINDLES

HSK63 24,000~40,000 rpm up to 42Kw

HSK100 7,000~12,000 rpm up to 550Nm

HSK100 7,000~12,000 rpm up to 550Nm

Built for precision.

Base machine cast iron structure for minimum thermal deviation and vibration, over sized linear guideways with dual symmetrical driving systems which are thermal stabilized.

Designed to achieve high performance machining in various materials without compromising the part’s precision.

Innovative Technology

Utilizing cutting edge technologies, we are able to provide all-around machines which fit most common applications.